High demand for bandwidth globally and the need to achieve sustainability targets have led to increased discussions on the carbon footprint of networks writes Oene-Wim Stallinga at Nexans.

Global demand for bandwidth has never been greater. At the same time the pressure to achieve sustainability and climate targets is increasing. As a result, the carbon footprint of networks is a widely discussed issue. There are several benefits related to critically evaluating carbon emission aspects of products and processes.

Not only can this support your own sustainability goals and lower operational costs, but it can also ensure better CO2 performance across complete projects, which is becoming an increasingly important factor in the selection of partners and suppliers.

When a provider, operator, or government commissions the rollout of a fibre network, sustainability is a more important consideration than ever. Everyone from incumbents and AltNets to equipment manufacturers is held to increasingly strict demands. This applies right across the entire supply chain. After all, the sustainability of an entire project will largely be determined by the weakest link in that chain.

Evaluating carbon emissions can lower operational costs, support sustainability goals, and improve CO2 performance in projects, which is an important factor in selecting partners and suppliers. However, expressing a commitment to CO2 reduction is not enough: you need to be capable of backing up these claims.

As more countries aim to become carbon-neutral in the coming years it will be vital for operators to monitor and record the carbon emissions caused by networks, including all related processes. This will be particularly important for operators migrating from traditional copper technologies to fibre.

In fact, CO2 reduction will be a driver in efforts to switch off copper networks. For network owners, sustainably designed and executed networks can be key to supporting corporate CSR and environmental policies, but studies also show that environmentally aware practices have a positive effect on companies’ competitive performance.

Apart from helping improve your CO2 performance, environmentally-friendly designs also support reduction of operational and business costs. Product eco-design means focusing on using less material, increasing the life span of components, and reducing weight. Light and thin cables can be packaged efficiently, with more cabling per drum, and transported using less fuel, for example. Smart designs mean that packaging, cables, and cable drums can be made, reused, and dismantled in ways that produce less CO2.

Longer lifespan minimises maintenance and repairs requirements and ensures fewer materials and less transport is needed. Reduced fault levels mean fewer truck rolls and therefore a reduction in carbon emissions.

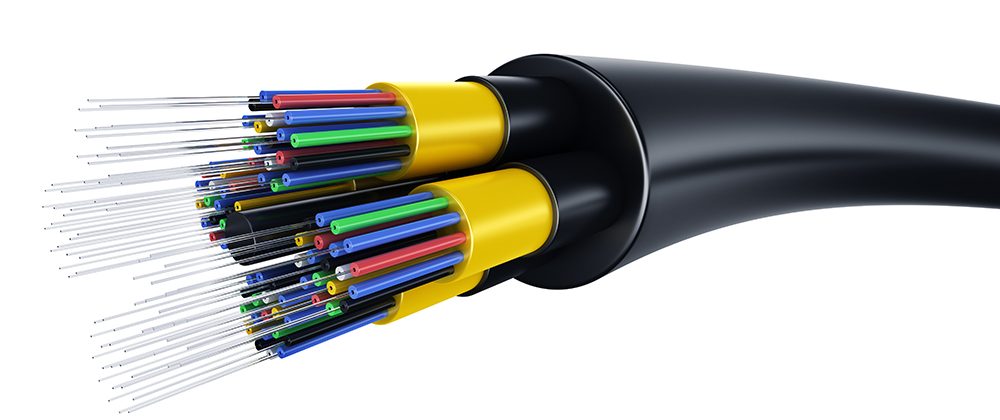

Fibre optic technology offers several inherent benefits when it comes to CO2 emission reduction. Its energy consumption is low, as a fibre network has fewer active components. Fibre networks emit 88% less greenhouse gasses per GB compared to legacy technologies. Data transmission performance headroom means that just one kilogram of glass is as powerful as 1,000 kilos of copper.

Looking at HD streaming, the lowest CO2 emissions are produced when using a fibre optic connection. Raw materials, including the silicate used for optical fibre, can be extracted, or recycled with a relatively low carbon footprint. Lighter weight and smart product and packaging designs reduce transport and waste-related emissions.

It will be vital for operators to record carbon emissions caused by networks, as operators migrate from copper technologies to fibre.

Green at Nexans

For several years now, Nexans has been committed to reducing its own carbon footprint and has also been working with its customers to reduce the carbon impact of infrastructure. Nexans’ solutions have been proven in the field: from cables and components to solutions for monitoring or damage prevention.

Here are just a few examples of how we are providing solutions that aim to support sustainable goals:

XPLORERTM optical drawers, widely used for coupling and cross-connects, benefited from advances in eco-design. By using reinforced thermoplastic instead of metal, the range significantly improves the environmental impact of the manufacturing phase on the 4 main indicators: global warming potential, 44%, abiotic depletion of resources, 93%, total primary energy consumption, 59%, and net fresh-water consumption 72%.

The INFRABIRDTM solution aims to avoid cabinet damage, break-ins, and disconnections, and can trace and time-stamp interventions, as well as send alerts. Technicians can gain access by identifying themselves with their smartphone, open and close the cabinet, and update their reports. In addition to the maintenance savings made by the operators, the CO2 reduction linked to the reduction in technician travel is estimated at 10,000 tons of CO2 equivalent for 20,000 cabinets.

Technician packs have been designed to group products needed to connect customers, PTO, offset cable, recycled jumper. By simplifying the associated logistics and optimising packaging, technicians limit their weekly trips to pick up their equipment; this represents a reduction of more than 600 kg CO2 equivalent per year per technician2.

250µm or 200µm blowable microcables are among the smallest on the market. They enable a reduction in weight and diameter and allow optimised sheath sizes. That means less material, less weight and volume to transport, and optimised civil engineering.

Nexans has started the switch to plastic-free bags and boxes, with its @XS range of optical outlets being the most recent to benefit. Like many in the industry, the vendor recognises that we still have a long way to go and cannot be complacent. However, we are committed to making this change quickly and efficiently.

By taking smart decisions when it comes to network design and product selection, these inherent benefits can be significantly leveraged. That means supporting your own environmental goals, reducing costs, and ensuring enterprises meet ever-stricter demands of potential partners and customers.

Thin cables can be packaged efficiently, with more cabling per drum, and transported using less fuel.